|

<Feature

of conventioal Microwave Furnace>

Conventional

Mircowave Furnaces have a problem in matching real

temperature with setting temperature

not only during raising temperature

but also during maintaining fixed temperature.

The temperature deviation can be resulted

in a couple of reasons.

One

of the most important reasons is that temperature

rise and fall are occuring too rapidly.

Temperature rises quickly when a magnetron

is on and then falls fastly when a magnetron

is off. Therefore, reducing temperature

deviation by controlling a magnetron is

not a simple method.

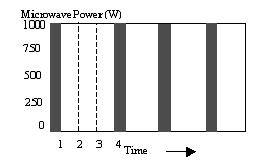

<Fig.

1> <Fig.

2>

<Fig.

1> and <Fig. 2>, respectively,

show different mechanisms which can be employed

to Microwave Furnace. <Fig. 1> shows

the On/Off control type. In this figure, temperature

rises quickly when microwave is radiating(black

section) and temperature falls swiftly when

microwave disappears(white section). Thus,

precise temperature contol is difficult.

<Fig. 2> shows Variable Power Microwave

Systems(VPMS) which was developed to improve

temperature equality. This method continuously

change power of magnetron between 0¡100%,

consequently temperature deviation is narrower

than On/Off control method. However, VPMS

method also has a weak point that its response

speed to magnetron power control is sluggish

because it drives stub by mechnical

manner such as a motor. As a result, this

method is not suitable for use in rapid

temperature rise in which power control

should be accomplished quickly. After all,

precise temperature control which is practicable

in an electric furnace is technically difficult

in a conventional Microwave Furnace, and

producing equipment to achieve accurate

temperature control will cost a lot of money.

In

spite of many advantages over a electric

furnace and a gas furnace, Microwave Furnaces

are not widely used because precise temperature

control is crucial for adjusting mechanical,

electircal properties of ceramics and metals.

<Microwave

Furnace of UNICERA>

To

solve this problem, the Microwave Furnace

of UNICERA adopts Micro-Time-Slicing mechanism.

This

mechnism control the cycle of manetron On/Off

in microscopic time. The cycle of Mico-Time-Slicing

mechanism is smaller than 1 second.

This is much shorter than the cycle of conventional

On/Off mechanism, for example 7 seconds.

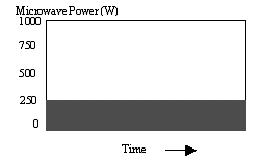

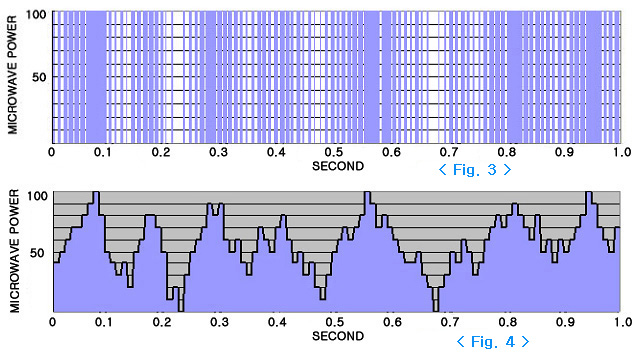

<Fig.

3> shows one example of the cyle of magnetron

On/Off controlled by Micro-Time-Slicing

mechanism. <Fig. 4> represents actual

Microwave power radiating an objects which

is the result of <Fig. 3>.

To

control magnetron power in microscopic time,

Microwave Furnace of UNICERA adopts temperature

controller which utilizes Micro-Processor

and Operating Program. One operating pulse

cycle consists of On and Off period. Operating

pulse cycle and each On/Off period can be

adjusted by an operator or operating program.

For example, if an operating pulse

cycle is 0.01 second, we can adjust such

as that 25% of the cycle is On

period and 75% of the cyle is Off period.

Operating time of UNICERA's Microwave Furnace should be set between

0.0001 ¡ 1 second. If operating time is

shorter than 0.0001 second, magnetron power

might be unstable. If operating time is

longer than 1 second, temperature deviation

problem might be occurred just like in conventional

On/Off control mechanism.

In

addition, our company's Microwave Furnace

can change the ratio of On/Off periods during operating.

That is, Micro-Processor loaded in Furnace

can control dynamically the ratio of On/Off

periods according to measured temperature

and programmed temperature schedule. For

example, if measured temperature is higher

or lower than programmed temperature, Micro-Processor

decreases or increases the ratio of On period

of the cycle.

|