|

Fig.

(a) shows microstructure of ZnO sintered

by UNICERA's Microwave Furnace at 1200¡É

for 5 minutes with heating rate of 100¡É/min.

Compared to Fig. (b) which shows microstructure

of ZnO sintered by a conventional electric

furnace at 1200¡É for 4 hours with heating

rate of 5¡É/min, Fig. (a) displays dense

microstructure with few pores in spite of

short sintering time. We can expect that, because

of the high heating rate and short sustaining

time, grain growth is almost prohibited.

In

addition, we can compare Zirconia sample

sintered by UNICERA's microwave furnace

with the one sintered by conventional Electric

furnace.

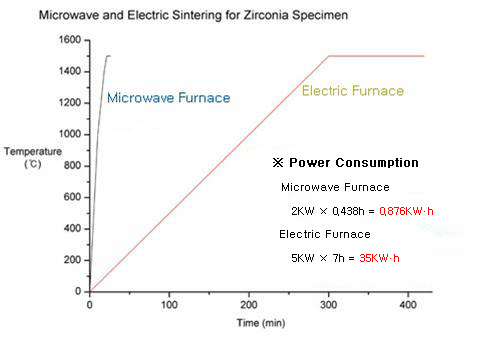

Fig.

(c)

Fig.

(c) shows the heating rate and duration

time of sintering by a Microwave furnace

and an Electric Furnace. As you can see,

by using a Microwave furnace, we raise the

temperature with the heating rate of 100¡É/min

up to 1000¡É and, with 50¡É up to 1400¡É

and then with 30¡É up to 1500¡É. We sustain

the temperature at 1500¡É for five minutes.

In contrast, by using an Electric furnace,

we raise the temperature with the heating

rate of 5¡É/min up to 1500¡É for 5 hours

and sustain the temperature at 1500¡É for

2 hours. The result of sintering following

these procedures are shown in pictures below:

.jpg)

.jpg)

Fig.

(d) Fig.

(e)

Fig.

(d) shows the microstructure of Zirconia

sintered bt an Elctric furnace and Fig.

(e) shows the microstructure of Zirconia

sintered by a Microwave furnace.

The

significant advantages of Microwave Sintering

include: (1) a short processing time

(shorter

than 1/20), (2) little

energy consumption (less

that 1/3), (3) increased

mechanical strength of a sintered material

owing to a high density and fine grain size.

|